Chemical manufacturers often rely on outsourced distributors and logistics companies to move products, shorten delivery schedules, streamline transaction costs, and to free up time for other priorities. In the past, chemical distributors focused on providing the labor and equipment required to transport products, and left the route logistics to firms which specialized in these tasks. However, the chemical distribution industry has evolved, and most chemical distributor companies add value by providing a mix of two or more services which include packaging, logistics, warehousing, mixing, blending, formulating, technical support, training, recycling, and more. Depending on the outsourced services required, multiple contracts may be initiated among 3PL vs. 4PL vs. 5PL service providers.

What Is a 3PL (3rd Party Logistics) Company?

A 3PL company refers to the “third party” who brokers logistical transactions between the shipping company and the company the 3PL was hired to represent. The role of the 3PL is focused on optimizing the specific tasks necessary to complete the transfer of freight.

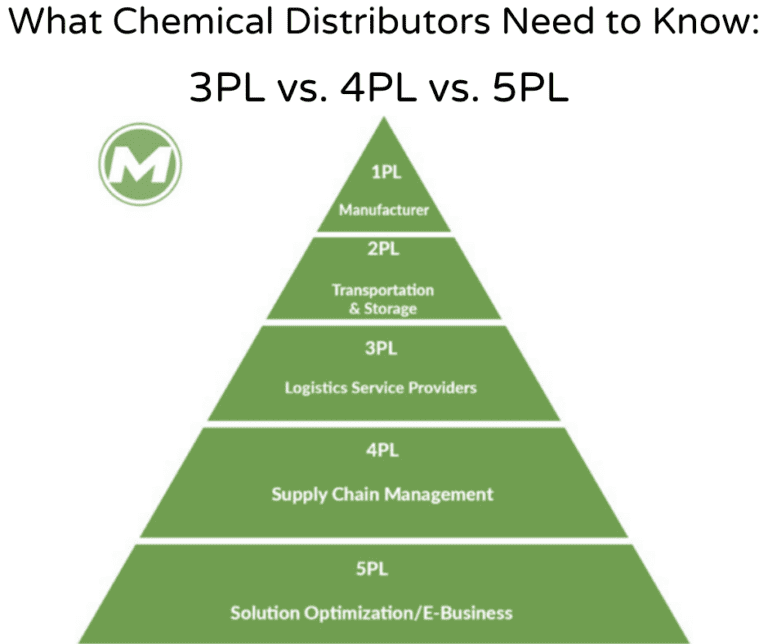

Since distinguishing between 3PL vs. 4PL vs. 5PL companies can be confusing, let’s start by considering the 1st party in the supply chain, sometimes called the “1PL”. The first party is the manufacturer who produces a product which must be shipped to the end user. Along the way, the product may require warehousing, processing, packaging, and further distribution.

The 2PL is the asset-based carrier or the traditional distributor responsible for the transport and storage of freight. Numerous 2PLs may handle the freight between the point of origin at the manufacturing facility and the point of final sale for consumption.

In very simple terms, 3PLs are the companies that provide outsourced logistics services to manage transactions amongst the 2PLs on behalf of the manufacturer. 4PLs manage a network of 3PLs and 5PLs work with multiple 3PLs and 4PLs to optimize transportation amongst numerous companies and cargo loads, typically focusing on e-commerce and technology solutions.

Skip the potential headaches that come with equipment ownership! Ask your transportation partner if they lease reliable liquid tank trailers from Matlack Leasing, the industry leader in ISO tank chassis.

Common Services Offered by Logistics Providers

3PL ACTIVITIES: |

4PL ACTIVITIES: |

5PL ACTIVITIES: |

| Warehousing | Warehouse Contract Management | 5PL providers construct, organize, and implement logistics on behalf of multiple clients with an extensive focus on technology and e-business solutions. 5PLs are committed to collaboration to minimize costs aggregating 3PL demands into bulk volumes for more favorable rates. |

| Transportation Services | Transportation Services Contract Management | |

| Packaging | Logistics Network | |

| Management | ||

| Cross-docking | Project Management | |

| Customs Clearances | Customs Transactions | |

| Inventory Management | ||

| Freight Inspection | ||

| Freight Forwarding |

Note: The mix of services offered will vary based on the business model of the company.

What is a 4PL?

A fourth-party logistics (4PL) provider is an independent, non-asset based integrator who acts as the main point of contact for the customer in determining and assembling resources and technology from both its own organization, as well as other 3PLs, in order to comprehensively run the client’s supply chain. Often, over time, 3PLs may evolve into a 4PL provider.

A 4PL provider focuses on the strategy and tactics required for efficient supply chain management, providing technology-based solutions, and often contracting with one or more 3PL providers for execution. 4PL providers offer companies access to experts with a holistic view of logistic operations.

The Difference Between 3PLs and 4PLs

The main difference between 3PL and 4PL companies is the control and accountability that the PL provider has over the customer’s supply chain. 4PLs provide the customer with a higher level of consulting services regarding their supply chain processes. These include:

- A neutral management,

- Impartial feedback,

- Efficiency, and

- Cost strategies.

Therefore, transparency, communication and trust are key skills required for 4PLs to provide optimal transportation solutions in order to meet customer specific objectives. More than just an outsourced vendor, the 4PL acts in lieu of the customer and must remain objective in their decision-making to serve the customer’s best interests. Organizations who use more than one 3PL without outsourcing to a 4PL are themselves responsible for finding, planning, and coordinating the relationships and logistics between all their 3PL providers.

What Are the Risks and Benefits of Outsourcing Bulk Chemical Transportation Activities?

Logistics providers most often focus on optimizing the transportation and handling of specific product lines in a particular geographic region. This is most clearly evidenced in the dynamic chemical industry marketplace, which offers logistics service providers the opportunity for close cooperation due to the special requirements of the goods being moved. 3PL, 4PL, and 5PL logistics providers bring efficiency to the supply chain and to chemical distribution channels by offering specialized combinations of technologies, equipment, relationships, expertise, and service. However, some manufacturers consider internal logistics a core competency and may be reluctant to share this responsibility.

When considering the risks and benefits of outsourcing bulk chemical transportation activities, it is important to identify your organization’s goals and objectives. A clear understanding of internal priorities and objectives will inform the decision-making process and aid in evaluating these risks and benefits.

The Advantages of Outsourcing Bulk Chemical Transportation

- Cost Savings – Logistics companies with access to additional resources, specialized equipment, and/or key relationships may pass on savings to their customers.

- Time Savings – Outsourcing logistics enables in-house experts to devote time to other priorities.

- Increased Efficiency – Outsourcing supply chain, warehousing, logistics, and management may result in shorter delivery times and improve customer satisfaction.

The Disadvantages of Outsourcing Bulk Chemical Transporting

- Upfront Investments – Outsourcing logistics should pay for itself in the long-run, but the initial cost can be high, particularly for low volume transactions4.

- Requires Change – Transition from internal control to an outsourced logistics provider requires a learning curve while employees are retrained and new procedures are established4.

- Loss of Control – Outsourcing requires relying on others to accomplish your objectives. It is important to carefully evaluate your 3PL and 4PL providers and work with a proven firm whom you trust. And to clearly communicate your desired outcomes.

Call Matlack for Bulk Chemical Transportation Equipment Leasing

How to Choose the Right Logistics Provider

When it comes to transporting chemicals, it is imperative to work with trained specialists who understand the chemical properties and hazards, safety communications and precautions, temperature requirements, and the shelf-life of the materials being moved, stored, and handled3.

The following are just a few questions to consider when selecting a logistics provider for your goods:

- Does the company have the specialization and experience to meet your defined organizational objectives?

- Do they employ quality equipment to transport your bulk liquid chemicals safely and efficiently?

- What technologies do they offer?

- Do they offer transparency?

- Do they have experience transporting similar products along the distribution route?

- How do they handle the legal requirements for the transportation of your product volume?

- Do they have available resources to meet your delivery schedule?

- What is their safety record?

- Does the company have a stellar reputation for transporting bulk liquids?

- How long has the company been in business, and have they been agile and flexible over time?

Do your research, compare providers, and above all make sure you choose a logistic provider whom you trust to be responsible throughout the transportation process. Research the companies that meet your criteria and send them an RFP. Also ask if they own their own equipment or lease reliable tank trailers and tank chassis from an established equipment asset provider such as Matlack Leasing, LLC.

Sources:

- Berman, Jeff. “Armstrong report points to the continued increase in 3PL usage by shippers.” Armstrong & Associates, Accessed September 2020.

- Kille, Christian, and Constantin Reuter. “Success Factors of 4PL, LLP, 3PL in Chemical Logistics.” DASCHER Chem-Logistics, Accessed September 2020.

- Patrick Burnson. “2020 State of Logistics: Third-Party Logistics (3PL)”, Accessed September 2020.

- Jami Deloe. “Beginner’s Guide to Using 3PL Providers”, Accessed September 2020.

*Links removed for sources no longer available.